Glass Coating

Glass is such a versatile surface that it can be used for virtually any function. It can be molded, tinted, toughened, frosted and used as shower screens, floors, rooftops, walls, mirrors, doors, kitchen splash backs and more.

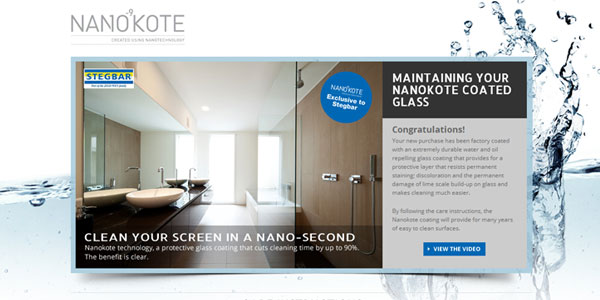

NANOKOTE’s glass corrosion coating and protection products are equally diverse in their practical applications—especially when surfaces are exposed to lime scale and sea spray. Enhance the durability and effectiveness of shower screens, pool fencing, balustrades, splash backs, architectural and frame-less panes with appropriate glass protection from NANOKOTE.

Our glass surface coating and protection products create easy-to-clean and anti-fingerprint properties that enable manufacturers and processors to add value and up-sell their products. These bonus properties create an opportunity to command premium prices and a competitive advantage in the marketplace.

90% less time cleaning

Over time, lime deposits can build up on shower screens and glass corrosion can result in permanent damage to the molecular structure of the screen. Glass corrosion may look like dirt but once it forms it cannot be removed, no matter how much the surface is cleaned.

NANOKOTE’s glass corrosion coating and protection stops corrosion by repelling water, dirt, oil, soaps and shampoo residues. With our glass corrosion coating and protection system, a shower screen will stay clear and bright requiring up to 90% less cleaning and will potentially never need to be replaced.

NANOKOTE is highly abrasion resistant, 100% UV stable and chemical resistant. It is also incredibly durable and is suitable for both interior and exterior applications. The glass coating protects external windows, commercial facades, rooftops, pool surrounds and balconies.

Industrial Integration

NANOKOTE has developed several processes to assist our industrial customers in reducing, and in some cases eliminating, the labor component of surface coating glass. We have engineered solutions for plants that process anywhere from 100 to 4,000 m² per day of glass. In the case of smaller processors, we recommend manual or semi-automatic applications, while medium to large organizations can benefit from our low cost, fully automated spray equipment which is modular and can be fitted to most processing facilities. Industrial application using automated equipment of NANOKOTE’s Easy Clean Coating vs. Competitors

Glass without Nanokote

Glass with Nanokote

| Nanokote | Typical Competitor | |

|---|---|---|

| Initial contact Angle (DIN EN 828) |

|

|

| ASTM Scrub Resistance (ASTM D2486) – Direct measure of durability |

|

|

| Coefficient of Friction (Slippery Feel) |

|

|

| Process Automation |

|

|

Glass Coating and Protection

For more information about NANOKOTE thin films, contact us.